On August 5th I had the chance to brew a batch of my Whale Tail Pale Ale with Doug Odell of Odell Brewing on his five-barrel system. My recipe was chosen during a homebrew competition at an AHA Rally at Odell, and the grand prize was having the recipe scaled up to commercial size and entered in the Great American Beer Fest Pro-Am competition. The batch is also currently on tap at the brewery's tap house and will be available for tasting at the GABF.

This was my first homebrew contest, and I was stunned to hear that I had won. I later found out that the judging panel had included Jeff Lebesch from New Belgium, Colin Westcott from Hops and Berries, and Ray Daniels, author of Designing Great Beers. Charlie Papazian almost made it as well. The recipe I entered was a Pale Ale that I have been tweaking for several years.

Doug and I traded a few emails to get the recipe down to begin with. Since I use a different strain of yeast than they do at the brewery Doug went to the local homebrew shop, bought a tube and began cultivating enough to use for a 155-gallon batch. He also set about trying to find hops to match the recipe.

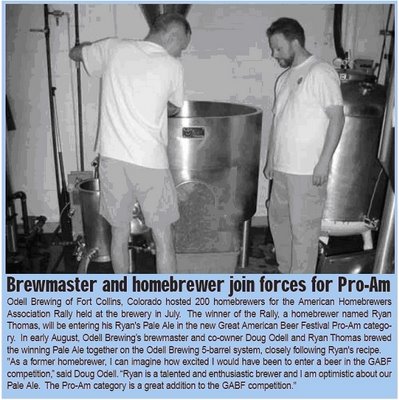

When the brewing day finally arrived I was very excited. I would be brewing almost half as much beer in one day as I had in several years of homebrewing. The process began as it always does: cleaning, cleaning, cleaning. All of the pieces got a thorough sanitizing and a good scrubbing. We then mashed in with 280 pounds of grain and let it rest until conversion was complete.

After recirculating and sparging the sweet liquor we pumped it into the boil kettle and started it heating. While waiting for it to boil I shoveled out the spent grains and cleaned the mash tun. Once that was finished we were almost at a boil. Once we had full boil I got to do one of the best parts of the whole process: adding almost a pound and a half of hop pellets. Nothing compares to the smell of hopping. I also added almost four more pounds of hops during the course of the brew. Being an American style Pale Ale the hops are to me the most important part of the whole recipe.

After boiling for 90 minutes we were ready to whirlpool the wort to help the hops settle out. Afterwards we ran the wort through a chiller to bring it down to 70 before pumping it into the conical fermenter. After that, the yeast was pitched and we were on our way to beer.

After primary fermentation was complete the beer was racked to a secondary fermenter and another six pounds of hops were add. Once complete the beer was chilled, filtered and then kegged. I've sampled the beer at their tap house, and I am very pleased with the way it turned out. It is nearly identical to the homebrew version. Being able to buy my beer on tap is an amazing feeling.

I had a wonderful experience brewing this beer with Doug Odell, and I learned a great deal from him. I also got to see and use a much larger setup than I would otherwise have had access to. While the principles are the same, there are a lot of different processes and equipment. The five-barrel system is full-fledged commercial beer production equipment, similar to what could run an entire brewpub. I have been planning to construct my own half-barrel system, and now I have some great ideas.

I'd like to thank Doug Odell for giving me the opportunity to be brewer for a day, all of the judges who liked my beer, the AHA for arranging the contest, and the Brewers Association for putting together the Pro-Am competition.

In all, this experience has taught me many things and has made me appreciate even more the culture of beer that exists along the Colorado Front Range. There are smart and talented people, great breweries and beers, and the AHA is always working to keep making things even better. Best of all, we are the home of the Great American Beer Fest. This year's Pro-Am will hopefully be the start of a long tradition. |